What is Continuous Improvement?

Continuous improvement, also known as continual improvement, is the ongoing effort to make small, incremental changes to products, services, or processes to enhance efficiency, quality, and overall effectiveness. Instead of seeking a dramatic overhaul, it focuses on steady progress over time. The concept originates from the Japanese philosophy of Kaizen, meaning “change for better.” While it began in manufacturing, it has since expanded into various industries, including technology, healthcare, and business operations.

How the Continuous Improvement Process Works

At its core, continuous improvement is about fostering a culture where everyone in an organization is encouraged to find better ways to work. These improvements may involve refining workflows, reducing waste, enhancing collaboration, or leveraging new tools. While some changes yield immediate benefits, others contribute to long-term success.

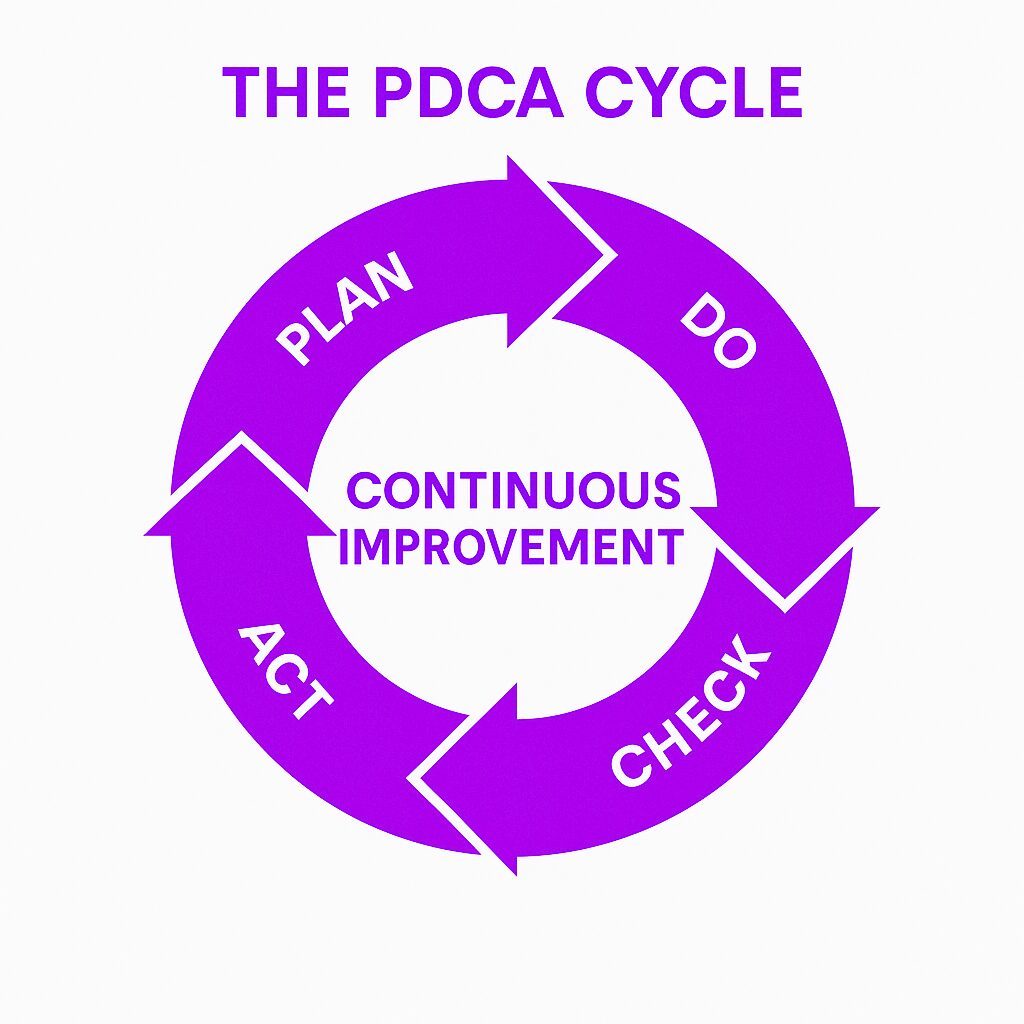

A key aspect of this approach is the continuous improvement cycle, a systematic method that businesses can adopt to enhance employee satisfaction, efficiency, and overall quality. The cycle involves the Plan-Do-Check-Act (PDCA) stages, emphasizing its iterative nature as an ongoing process where each phase contributes to refining and optimizing operations over time.

The process follows a structured approach:

-

Identify areas for improvement – Gather feedback, analyze inefficiencies, and recognize opportunities.

-

Implement small, manageable changes – Introduce adjustments that won’t disrupt operations but will lead to progress.

-

Evaluate the results – Measure the impact and determine if further refinement is needed.

-

Standardize successful improvements – Once a change proves effective, integrate it into regular workflows.

The Core Components of Continuous Improvement

1. The Plan-Do-Check-Act (PDCA) Cycle

This four-step model, also known as the Deming Cycle, is a core component of the continuous improvement cycle and is widely used to drive improvements:

-

Plan: Define the problem and develop a strategy.

-

Do: Test solutions on a small scale.

-

Check: Analyze the outcomes and gather feedback.

-

Act: Implement the successful changes on a broader level.

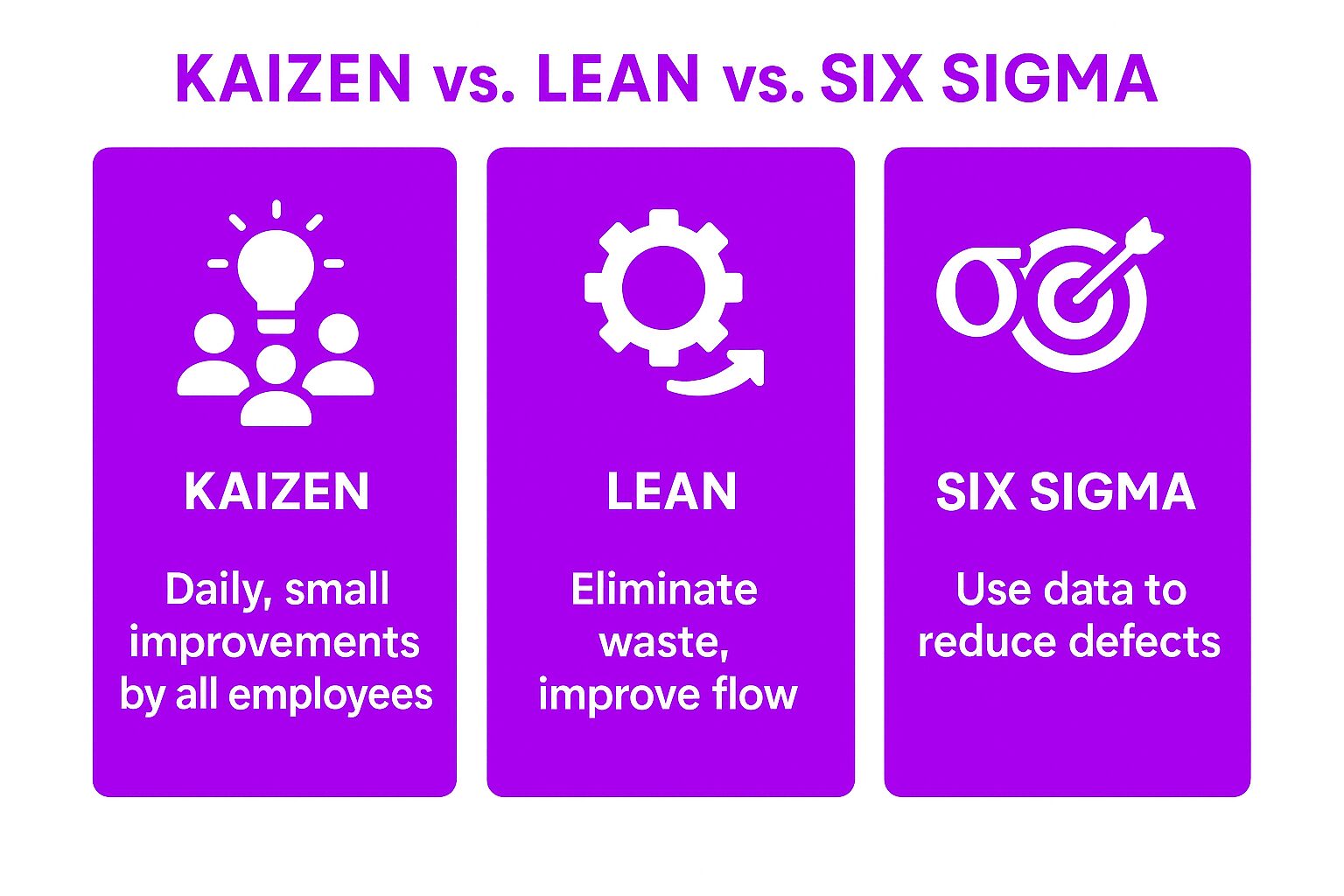

2. Kaizen

Kaizen is a Japanese business philosophy that promotes continuous learning and improvement. Unlike large-scale initiatives, Kaizen focuses on daily, incremental changes led by employees at all levels. This approach encourages a proactive mindset where workers are always seeking ways to enhance their tasks.

3. Lean Methodology

Lean management aims to eliminate waste and optimize processes. It focuses on improving workflows by reducing unnecessary steps, preventing defects, and maximizing efficiency. It is widely used in manufacturing, healthcare, and software development.

Lean methodology integrates with the continual improvement process by recognizing and implementing incremental enhancements across various systems and services.

4. Six Sigma

Six Sigma is a data-driven methodology designed to reduce errors and improve quality. It follows a structured problem-solving approach using statistical analysis. Many organizations use Lean Six Sigma, a combination of Lean and Six Sigma principles, to drive operational excellence. Six Sigma incorporates various continuous improvement methods to enhance quality and efficiency in process improvement teams.

5. Agile and Iterative Improvement

Agile methodology is common in software development but applies to other industries as well. It promotes continuous feedback, iteration, and adaptability. Teams frequently assess progress and make adjustments to enhance performance.

6. Root Cause Analysis and the 5 Whys Method

Root cause analysis is a fundamental technique in the continuous improvement model, aimed at identifying the underlying causes of problems rather than just addressing their symptoms. One of the most effective methods for root cause analysis is the 5 Whys method. This technique involves asking “why” multiple times—typically five—to drill down to the root cause of an issue.

The 5 Whys method is straightforward yet powerful. Here’s how it works:

-

Identify the problem: Start by clearly stating the problem.

-

Ask why: Question why the problem is occurring.

-

Ask why again: Dig deeper by asking why the identified cause is happening.

-

Repeat: Continue this process until you reach the root cause, usually after five iterations.

For instance, consider a company facing issues with defective products:

-

Why are we experiencing defective products? (Answer: The manufacturing process is not being followed correctly.)

-

Why is the manufacturing process not being followed correctly? (Answer: Employees are not properly trained.)

-

Why are employees not properly trained? (Answer: The training program is ineffective.)

-

Why is the training program ineffective? (Answer: It is not updated regularly.)

-

Why is the training program not updated regularly? (Answer: There is no process in place for updating the training program.)

In this example, the root cause is the lack of a process for updating the training program. Addressing this root cause can lead to significant process improvement and improved quality of products.

Why Continuous Improvement Matters

A commitment to continuous improvement helps businesses remain competitive and adaptable. It ensures processes remain relevant and effective, leading to better outcomes for employees, customers, and stakeholders. A continuous improvement journey emphasizes the importance of incremental changes over time, starting small and focusing on manageable improvements, which can lead to significant results.

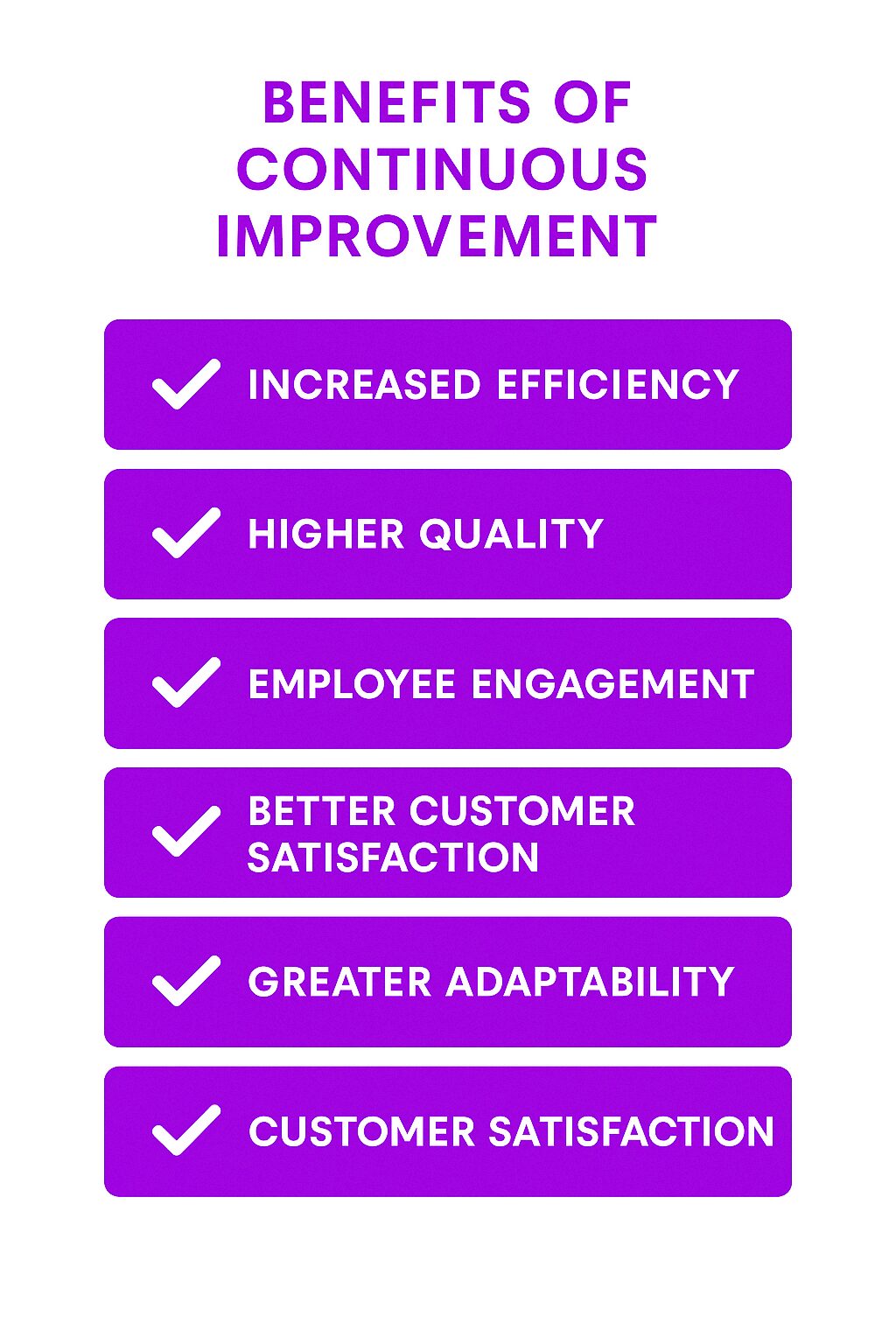

Key benefits include:

-

Increased efficiency – Eliminating unnecessary steps reduces wasted time and effort.

-

Higher quality output – Incremental refinements lead to better products and services.

-

Employee engagement – Involving teams in improvement efforts fosters motivation and ownership.

-

Better customer satisfaction – Enhanced processes result in improved experiences for clients.

-

Adaptability – Organizations can quickly respond to industry shifts and evolving needs.

Challenges of Continuous Improvement

While the benefits are significant, organizations may face obstacles when implementing continuous improvement initiatives. Common challenges include:

Resistance to Change

Employees may be reluctant to embrace new processes, especially if they feel comfortable with existing workflows. Effective communication, training, and leadership support are essential to overcome resistance.

Lack of Clear Objectives

Without well-defined goals, improvement efforts may become disorganized or ineffective. Establishing measurable targets ensures progress remains on track.

Resource Constraints

Time, budget, and expertise can limit the ability to implement changes. Prioritizing high-impact improvements and leveraging available technology can help mitigate this issue.

Measuring Success

Tracking progress can be difficult without clear metrics. Organizations should establish performance indicators to assess whether changes are producing desired results.

Practical Strategies for Implementing Continuous Improvement

1. Foster a Culture of Improvement

Encourage employees to take initiative and contribute ideas for incremental improvement in workflows. Recognizing and rewarding innovation helps sustain motivation.

2. Use Data to Drive Decisions

Leverage key performance indicators (KPIs) to identify inefficiencies and measure the impact of changes. Data-driven insights provide clarity and direction.

3. Encourage Cross-Functional Collaboration

Different departments should work together to identify pain points and share best practices. Open communication ensures improvements align with overall business goals.

Leverage Technology and Continuous Improvement Tools

Automation, AI, and digital tools can streamline processes and reduce manual effort. Implementing the right software solutions can enhance productivity.

5. Train and Develop Employees

Providing training on problem-solving methodologies and process improvement techniques equips teams with the skills needed to drive continuous improvement.

6. Feedback Mechanisms for Continuous Improvement

Feedback mechanisms are crucial for a successful continuous improvement process. They provide a structured way for employees to share their insights and suggestions for enhancing processes and operations. Effective feedback mechanisms can take various forms, including suggestion boxes, employee surveys, focus groups, one-on-one meetings with supervisors, and regular team meetings.

These mechanisms are vital because employees are often closest to the processes and can offer valuable perspectives on how to improve them. To ensure feedback mechanisms are effective, organizations should:

-

Make them easy to use and accessible to all employees.

-

Ensure feedback is anonymous and confidential to encourage honest input.

-

Provide regular updates on the status of suggestions to show that feedback is valued.

-

Recognize and reward employees for their contributions to the continuous improvement process.

By fostering an environment where feedback is encouraged and acted upon, organizations can continuously refine their processes, leading to incremental improvements and enhanced customer satisfaction.

7. Creating a Vision and Defining Measurable Goals

Creating a vision and defining measurable goals are essential steps in the continuous improvement process. A clear vision provides direction and inspiration, while measurable goals ensure that everyone in the organization is working towards the same objectives.

A vision statement should articulate what the organization aims to achieve in the long term. It should be inspiring, motivating, and provide a clear direction. Measurable goals, on the other hand, are specific objectives that align with the vision statement. These goals should be challenging yet achievable, and they must be measurable and trackable.

When creating a vision and defining measurable goals, it’s important to ensure they are:

-

Aligned with the organization’s mission and values.

-

Challenging yet realistic.

-

Clearly communicated to all employees.

-

Regularly reviewed and updated to reflect progress and changing circumstances.

By setting a clear vision and measurable goals, organizations can maintain focus and drive continuous improvement efforts that lead to improved quality and customer satisfaction.

Continuous Improvement Tools and Methodologies

There are numerous tools and methodologies available to support the continuous improvement process. Some of the most widely used include:

-

Lean: Focuses on eliminating waste and streamlining processes to enhance efficiency.

-

Six Sigma: Uses data-driven techniques to reduce errors and improve quality.

-

Total Quality Management (TQM): An organization-wide approach to quality management that integrates continuous improvement principles.

-

Kaizen: Emphasizes daily, incremental improvements led by employees at all levels.

-

Kanban: A visual tool for managing and tracking work, often used in Agile environments.

-

Agile: Promotes continuous feedback, iteration, and adaptability, commonly used in software development.

Each of these tools and methodologies has its strengths and can be chosen based on the specific needs and goals of the organization. By leveraging the right tools, organizations can enhance their continuous improvement efforts and achieve better outcomes.

Kanban Boards and Their Application

Kanban boards are a highly effective visual tool for managing and tracking work. Originating from Lean methodology, they are widely used in software development and IT but can be applied to any process or operation.

A typical Kanban board consists of three columns:

-

To-Do: Lists all tasks that need to be completed.

-

In-Progress: Shows tasks currently being worked on.

-

Done: Displays tasks that have been completed.

Kanban boards provide a clear visual representation of the work process, helping teams to see what needs to be done, what is in progress, and what has been completed. This visibility helps in identifying bottlenecks and streamlining processes.

To effectively implement a Kanban board, ensure it is:

-

Easy to use and understand.

-

Visible to all team members.

-

Regularly updated to reflect the current status of tasks.

-

Used to track progress and identify areas for improvement.

By using Kanban boards, organizations can enhance their continuous improvement efforts, leading to more efficient workflows and improved quality of outputs.

Examples of Continuous Improvement in Action

Toyota Production System

Toyota’s Kaizen approach is one of the most well-known examples of continuous improvement. Employees at all levels suggest ways to optimize manufacturing processes, leading to enhanced efficiency and reduced waste.

Healthcare Process Optimization

Hospitals use continuous improvement to streamline patient care. A medical center applying Lean Six Sigma increased its outpatient CT scan capacity by 45% without adding staff or equipment, simply by improving scheduling and workflow.

Agile Software Development

Tech companies use Agile principles to release software updates more frequently. By continuously refining code, addressing bugs, and incorporating user feedback, they ensure better performance and user experience.

Related Concepts

Operational Excellence

A broader term that encompasses continuous improvement, operational excellence aims to achieve peak efficiency and performance through systematic enhancements.

Total Quality Management (TQM)

TQM focuses on organization-wide quality control, integrating continuous improvement principles to enhance customer satisfaction and reduce defects.

Design Thinking

A problem-solving approach that fosters innovation through iteration and customer-centric design. It shares similarities with continuous improvement by emphasizing learning and adaptation.

Final Thoughts

Continuous improvement isn’t a one-time project—it’s a mindset. By making small, consistent changes, organizations can drive meaningful progress and stay ahead in a competitive landscape. Whether applied to business operations, technology, or customer service, the principles of continuous improvement create lasting benefits for everyone involved.